GNOME 2 was fun and easy. It felt like they were trying to learn from the mistakes of Windows and Mac UIs.

I once met a person that never drank water, only soft drinks. It’s not the unhealthiness of this that disturbed me, but the fact they did it without the requisite paperwork.

Unlike those disorganised people I have a formal waiver. I primarily drink steam and crushed glaciers.

GNOME 2 was fun and easy. It felt like they were trying to learn from the mistakes of Windows and Mac UIs.

Ooh thankyou for the link.

“We can leverage it [ray tracing] for things we haven’t been able to do in the past, which is giving accurate hit detection”

“So when you fire your weapon, the [hit] detection would be able to tell if you’re hitting a pixel that is leather sitting next to a pixel that is metal”

“Before ray tracing, we couldn’t distinguish between two pixels very easily, and we would pick one or the other because the materials were too complex. Ray tracing can do this on a per-pixel basis and showcase if you’re hitting metal or even something that’s fur. It makes the game more immersive, and you get that direct feedback as the player.”

It sounds like they’re assigning materials based off the pixels of a texture map, rather than each mesh in a model being a different material. ie you paint materials onto a character rather than selecting chunks of the character and assigning them.

I suspect this either won’t be noticeable at all to players or it will be a very minor improvement (at best). It’s not something worth going for in exchange for losing compatibility with other GPUs. It will require a different work pipeline for the 3D modellers (they have to paint materials on now rather than assign them per-mesh), but that’s neither here nor there, it might be easier for them or it might be hell-awful depending on the tooling.

This particular sentence upsets me:

Before ray tracing, we couldn’t distinguish between two pixels very easily

Uhuh. You’re not selling me on your game company.

“Before” ray tracing, the technology that has been around for decades. That you could do on a CPU or GPU for this very material-sensing task without the players noticing for around 20 years. Interpolate UVs across the colliding triangle and sample a texture.

I suspect the “more immersion” and “direct feedback” are veils over the real reasoning:

During NVIDIA’s big GeForce RTX 50 Series reveal, we learned that id has been working closely with the GeForce team on the game for several years (source)

With such a strong emphasis on RT and DLSS, it remains to be seen how these games will perform for AMD Radeon users

No-one sane implements Nvidia or AMD (or anyone else) exclusive libraries into their games unless they’re paid to do it. A game dev that cares about its players will make their game run well on all brands and flavours of graphics card.

At the end of the day this hurts consumers. If your games work on all GPU brands competitively then you have more choice and card companies are better motivated to compete. Whatever amount of money Nvidia is paying the gamedevs to do this must be smaller than what they earn back from consumers buying more of their product instead of competitors.

really flashy guns and there is a very intricate damage system that runs at least partially on the GPU.

Short opinion: no, CPU’s can do that fine (possibly better) and it’s a tiny corner of game logic.

Long opinion: Intersecting projectile paths with geometry will not gain advantages being moved from CPU to GPU unless you’re dealing with a ridiculous amount of projectiles every single frame. In most games this is less than 1% of CPU time and moving it to the GPU will probably reduce overall performance due to the latency costs (…but a lot of modern engines already have awful frame latency, so it might fit right in fine).

You would only do this if you have been told by higher ups that you have to OR if you have a really unusual and new game design (thousands of new projectile paths every frame? ie hundreds of thousands of bullets per second). Even detailed multi-layer enemy models with vital components is just a few extra traces, using a GPU to calc that would make the job harder for the engine dev for no gain.

Fun answer: checkout CNlohr’s noeuclid. Sadly no windows build (I tried cross compiling but ended up in dependency hell), but still compiles and runs under Linux. Physics are on the GPU and world geometry is very non-traditional. https://github.com/cnlohr/noeuclid

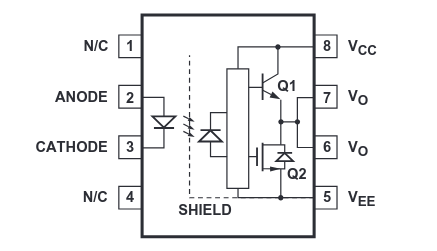

Triangle is an amplifier and rectangle is a black box (“don’t worry what’s in here, we promise it’s not gremlins”).

I suspect that the box might be a biasing array for driving the two output transistors, but then I would also expect two wires to come out of it (one for each transistor) rather than a single combined wire.

Broadcom’s datasheet for their version of the part seems to be more akin to what I’m thinking:

Could be either. You’d have to decap the chip to find out, the datasheet writers thought these details were not important.

I have no idea why two of the output pins are tied together. They’re not using many of the pins on this package so maybe they thought “why not”. I’ve also seen dual-optocouplers in this same 8 pin package where pins 6 & 7 are the outputs of the two separate couplers.

Some guy at the factory is removing the third paper from every unit before it gets boxed.

So many CMCs seem to be marketed based of visual appearance and hope. I guess maybe people already have a design that works, so they go for things that look like clones visually? Otherwise I don’t get how anyone would choose their product when there are alternatives with actual specs.

Another gripe: When the only datasheet available is a combined one with tables and graphs listing the specs of dozens of part variants. But yours isn’t on there. So you find two similar models in the list and mentally interpolate between the graphs whilst worrying whether or not this is a long-term supply item or some spares that a retailer is selling off from a custom order run.

I just realised how hard it would be to manufacture this thing.

Imagine having to bend those copper wires into that shape around an already-existing toroid ring. Or maybe they glue together a few pieces of ring?

Rotational symmetry :) EDIT: Wait no the paper! Arrrgh

It’s 50 bucks though. Too expensive of a date for me.

In the picture are 3 coiled wires, all sharing the same dark grey ring/toroid (but it looks yellow because it is wrapped in yellow kapton tape).

If you try and send the same signal through each of these 3 wires then they will all fight and cancel each other out (a bit like 3 people trying to through the same narrow doorway at the exact same time; no-one gets through). If the signals are different on each wire then they will get through fine (a bit like people going through a door at different times).

common mode chokes = choke/kill the signals that are common/same on all wires

You typically do not want common mode signals to exit your device and travel along cables, because then these cables act like radio transmitters. The exact reasoning for that is a bit more than I want to write here, but it’s best explained with some pictures and phrases like “you turned your cable into a monopole you doof, use more common mode chokes and think of England”.

Internally these devices work using magnetic fields in the dark-grey (ferrite) ring. I’m more familiar with 2-wire chokes where the coils are wound in opposite directions (so the magnetic fields they make cancel out), I am not sure how it works for 3 windings.

Microchannel coils: Wow. I assumed the pressures were too high for such construction to succeed. Thankyou :)

Fluid metering: I was aware of TXVs and capillary tubes, but not reverse bypass piston inserts. Would these options only be a few dollars difference in BOM price between each other? I guess the extra labour from soldering more pipes and connections for a TXV might be more costly than the extra materials themselves.

A vs N folded coils: interesting. I have mostly seen split systems and their unfolded coils, not central AC units with these A & N folded coils.

heat pumps instead of traditional compressor based ac systems

Heat pumps are compressor based systems. They are the same technology.

In addition to advances in fin design and compressor and motor efficiency and materials

This reads lot like an answer from an LLM. Did you use one? My apologies if not, but you sound very suspicious.

Definitely. Absolute scams. They deserve the “0 energy stars” ratings I’ve seen printed on their boxes.

My family bought one of those for one of my grandparents. On a 35degC day it was only able to cool the room by a few degrees and it was still humid inside.

Converting them into dual-hose systems would be so simple (almost free) to the manufacturer, but instead they rely on deceiving buyers with a promise of something that is not delivered.

:(

They really don’t put much plastic in these things.

I hope for a world where little phone competitors are more viable, then we might see some actually caring about bits like this. There are a few but they’re expensive and I balk at the cost of new phones anyway (I use second hand ones off eBay).

As a general rule I hold suspicion to any marketing that claims that using CO2 (or other products of burning) is environmental friendly. The products you get from burning fuels are supposed to be useless and of low value, otherwise they are not burning them efficiently.

To turn CO2 into potassium carbonate (pearl ash) you will need a lot of energy. Where they get this energy from is far more important than where they got the CO2 from. I would not be surprised if it is more environmentally friendly to make the pearl ash through a different process and ignore the CO2 rather than trying to convert the CO2 into pearl ash.

Background chemistry

Fuels are chemicals with a lot of potential chemical energy stored in them. They are generally considered (at a minimum) flammable or “reactive” in some way.

When we burn fuels we turn them into products with very little potential chemical energy, mainly CO2. You cannot burn CO2 and get energy out of it, it is a “stable” or “unreactive” chemical. It has very little chemical energy stored in it compared to the original fuel.

The difference in stored chemical energy between the fuel (eg methane CH4) and the products (eg CO2) is turned into heat and then electricity (via steam turbines). If your products are still reactive then you have not used them to their full potential and you will not get as much heat out as you could (not to mention improperly burned products tend to be toxic, eg carbon monoxide).

Now let’s look at potassium carbonate (K2CO3). It’s a somewhat reactive chemical, it’s not anywhere as stable as CO2, you can observe this by the fact it readily wants to react with other chemicals (caveman test: put it on your skin and it will sting). CO2 is very stable and does not want to do much (caveman test: put it on your skin and you won’t feel it).

To make K2CO3 from CO2 you will require energy input. Turning an unreactive chemical into a reactive one is a bit like the reverse of burning something. This energy will probably come from burning more coal or gas. I suspect it will require more coal/gas than making the CO2 did, so net overall you will probably be releasing more CO2 than you capture and turn into K2CO3.

Of course if they’re using renewal energy (solar) for this step then this could be a net positive.

My level of trust in the honesty of product packaging and marketing is pretty low and if they don’t mention it then they obviously don’t think it’s important. 🤷

EDIT: I’ll also add that “carbon capture” projects (things that claim to get rid of or make use of the CO2 from burning fuels) are universally disasters or scams.

EDIT2: I’ve taking some simplification liberties with the chemistry here. Technically CO2 isn’t completely stable, you can do stuff like make weak acids in water with it, but I do not believe anyone has found a way for that to usefully use up what we emit from burning fuels.

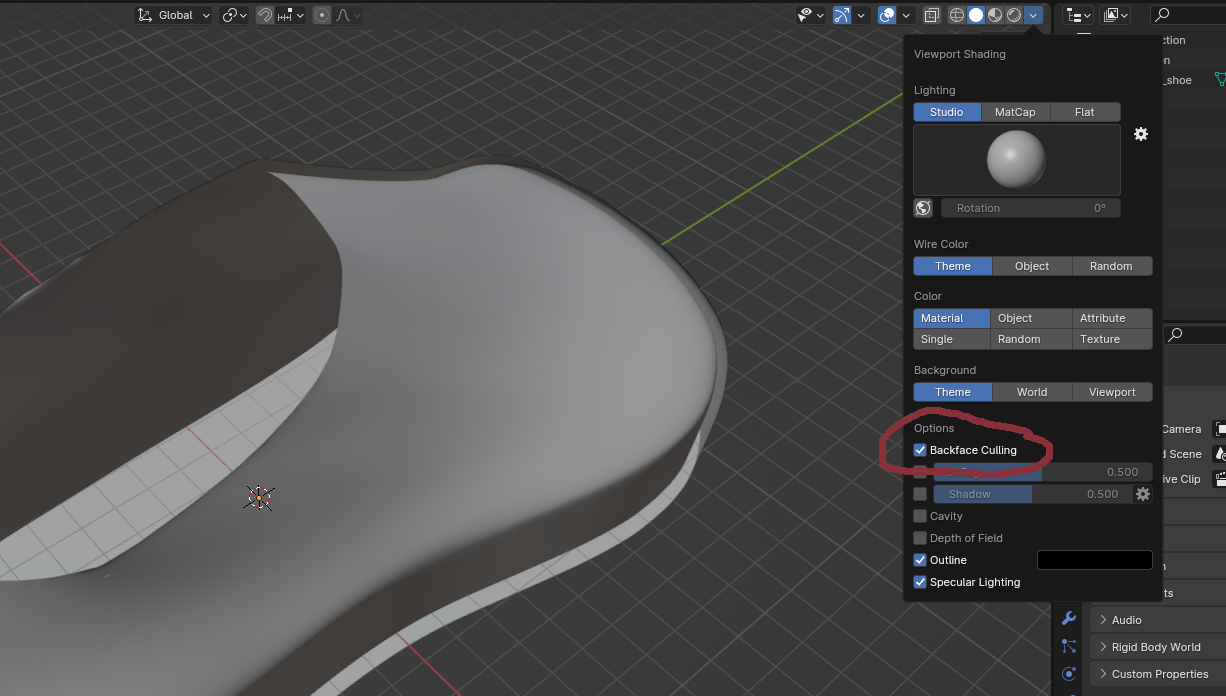

All of the the surface normals are backwards. This means your shoe is inside-out; instead of being a solid shoe in a vacuum it’s a shoe-shaped-hole inside a solid universe.

By default blender renders all polys as double-sided so you mostly don’t notice (other than some lighting oddities near corners). Turn on backface culling if you want to check if your normals are the right way around or not.

I often end up with some of my polys backwards because of the way I extrude and join parts of my models. I distinctly remember a bug in Gmax (old free version of 3DSmax) where the mirror tool would create polygons with some special, broken property where their normals would be correct in the editor, but completely wrong when exported :( much time and hassle was lost to that.

!?!?! Aussie.zone says this was posted “12 hours ago”, how did I miss this major development all day?

Oh. -_-

Would it be possible to edit this article to point to the archive.org link, then create a new post for the new news? Not sure if you want to at this point, you’re probably sick of this roundabout. Thankyou for sharing it all.

it would be interesting to know if the hole is connected right through to the barb or not

I feel very uncomfortable with the thought of probing this thing with long metal rods whilst looking down the end.

maybe hint it to police

I guess I could try and send them the pics and ask them about this “suspicious object”. Hopefully it’s just a bong.

(I can’t quite see it being an arsenic cannon, but yeah I wasn’t planning on trusting my copper oxide assumption regardless xD)

I was going to reply with “you can’t use barbed fittings at high pressures”, but I looked it up and found some claiming 150psi (10 atmospheres). Huh. Perhaps this did start life as a hydraulic cylinder that has had some parts lopped off.

Not sure what the tube is filled with, but it looks like a lot of corrosion.

I don’t think it’s built up corrosion. The pipe is steel and corrodes to red/brown iron oxide, as visible around the circumference at the end. The green colour in the filling is not an iron oxide. It might be a copper oxide, or some dye in the white material.

It looks identical to me. Same size before clicking, same size after right clicking -> Open image in new tab.