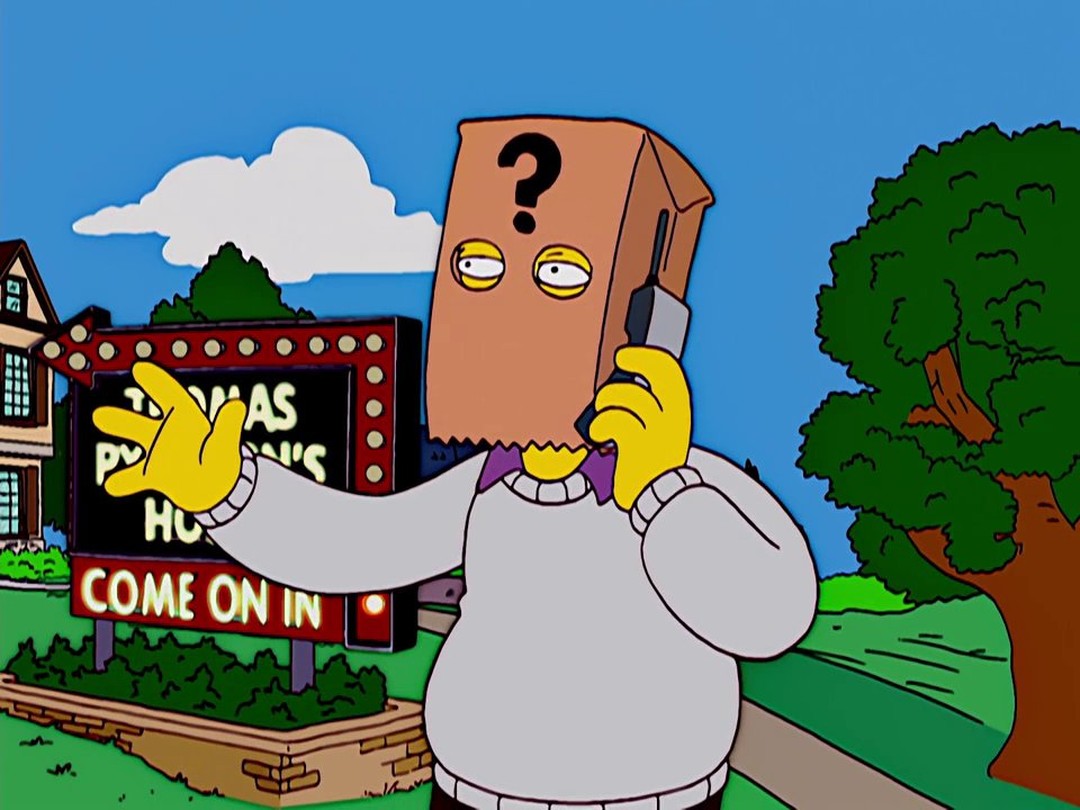

Pics of new vs old heating element

OEM or generic? I replaced mine a few months back and the sensors/thermal fuses with an off brand kit and it’s been nothing but a hassle since.

Twice more I’ve had to take it apart and replace a blown thermal fuse I finally just put the old ones back in, crossing my fingers that does the trick.

Yeah, the heating element in my oven went out. I didn’t want to trust some random Chinese Amazon one. I went ahead and bought the replacement directly from GE. It was like $25 more, but imo, very worth it. With the amount of wattage going through that, and potential for fires and failure, it was $25 well spent.

Dryers are one of the easiest machines to repair. They will also last forever, a lot longer than a washer.

Dangerously close to not being dull

Elementary, my dear Watson.

Oh snap. I read that the first way before reading it the second way. Magnificent work, sir or madam.

I don’t get it

The photo is of a clothing dryer heating element. The quote is from Sherlock Holmes implying that something is simple (elementary).

What was done was an English language pun.

very good

Consider a heat pump dryer. They use way less energy and make the house much less humid by condensing the water for drainage. It is a much more efficient system and saves money over the fairly short term.

I am shocked at how good my heat pump dryer is. It gets surprisingly hot, but not so hot that it’s harmful to the clothes. It dries like a charm. It also means I’m not pumping my expensive heated indoor air out of the vent all winter long, either, saving even MORE energy. Downside, it also uses a lot more technology, and the way they design technology nowadays, it’s probably got a counter inside it designed to intentionally self-destruct the moment they stop selling repair parts for it.

Who am I kidding though, they probably don’t sell repair parts for it at all, it’s just a countdown timer for when their financial projections require me to buy my next heat pump dryer.

Lol, true, the planned obsolescence is real. That said, I use Choice, a consumer advocacy group in Australia. They do reviews of products independent of the organisations they are reviewing. They get their funding from member subscriptions, not deals with manufacturers, so their financial interests are well aligned. They reviewed my washer and dryer and said they were the quietest and close to the most energy efficient available. If they die in a few years I will have made the difference up in electricity usage savings and not going mad from the noise, so it seems like a good deal.

The left looks more like a non-heating element.

What brand drier might I ask. I had a beloved stacked dryer and looked into getting it repaired. Once I had it opened and found the details, it became apparent the situation was hopeless and a new drier as in our future.

Basic appliance repair should be easy as pie, but the problem has been sourcing parts, having appliances that are actually built to be repaired (as in they don’t have to be destroyed to get to certain components.

Maytag. Only 5 years old

Well the old one was cooked

Mine failed the same way in the same spot a month ago. Interesting!

Not accidental. New consumer devices (last 30-ish years) make me think of the quote from Kung Pow, except that companies are purposely designing them wrong to shorten their service life, and make it impossible to repair them without scrapping another unit for parts.

companies are purposely designing them wrong to shorten their service life

This 100%. And specifically for readers unfamiliar with how product R&D works, the malice doesn’t even have to metastasize throughout a whole company in order to design inferior products. The following summarized, fictional exchange should depict the problem:

Management: we see Competitor X released a new light bulb that lasts 800 hours and costs $1. We need our own light bulb product, with at least 40% gross margin.

Marketing: OK, we can be competitive if we make a 1000 hour light bulb and consumers are willing to buy it for $1.10. We can maintain 40% gross margin if our cost per unit is less than 25 cents.

Engineering: OK, we’ll go work on that

[3 months later]

Engineering: right, we’ve built this light bulb that lasts 1500 hours avg (std dev of 100 hours) and only uses bog-standard tungsten from our long-term supplier, so the cost is 20 cents per unit

Marketing: nice, but we don’t need 1500 hours. Can we reduce the cost per unit further?

Engineering: What? But we’re already below 25 cents.

Marketing: No, you see, management wants at least 40% gross margin. More margin, more profit, more better.

Engineering: No, you don’t see. We’re already using the thinnest tungsten possible. We can’t change an element’s melting point, we can’t draw it any narrower, we can’t do … [insert ten other reasons why pursuing further savings is of diminishing return]

Marketing: This is an ultimatum: we cannot accept this product into production unless it meets exactly the specification we wrote. We will cancel the project and outsource R&D if you cannot achieve this.

Engineering: WTF??

[a month later]

Engineering: Per your

insanerequest, we have produced this light bulb with 1000 hours (std dev of 400 hours), by taking the earlier design and knicking the tungsten filament every few millimeters, so that those thin points will eventually fatigue and break. The cost to do this knicking is an extra 1 cent, but the material savings is 2 cents, so we are now at 19 cents per unit. But the std deviation shows wildly varying behavior for when any particular bulb will fail. /exasperated sighMarketing: Excellent! We’ll ship it!

Engineering: …

When the incentive structure is bad, all sorts of perverse results will occur, even for well-meaning participants. I leave it to you, dear reader, whether R&D’s complicity with such perverse, capitalistic goals is morally damning, but the fact remains that if a company does develop a superior product, it might just never see the light of day, or will be intentionally delayed/deferred until needed for “competitive” reasons. This is one possible mode, but the other would be to chronically underfund R&D, so that superior products cannot possibly be developed, barring a spontaneous and unplanned stroke of genius.

To that end, whichever the cause, the result is all the same: the guise of “competition” is actually a local minima, where the thread-bare minimum is accepted as a maximum, where maximum profit can be extracted. Why put money into innovation if no one else is? Why compete when all the other competitors know the game as well: all will save costs by maintaining the mediocrity. It’s like monopolies and trusts from a hundred years ago, but they don’t even need to say a word to each other in order to collude.

Legitimately pissed at the accuracy of this analogy, I fucking hate these people so much.

Shit, good thing you did, that one on the left looks like the beginnings of a helluva insurance payout.